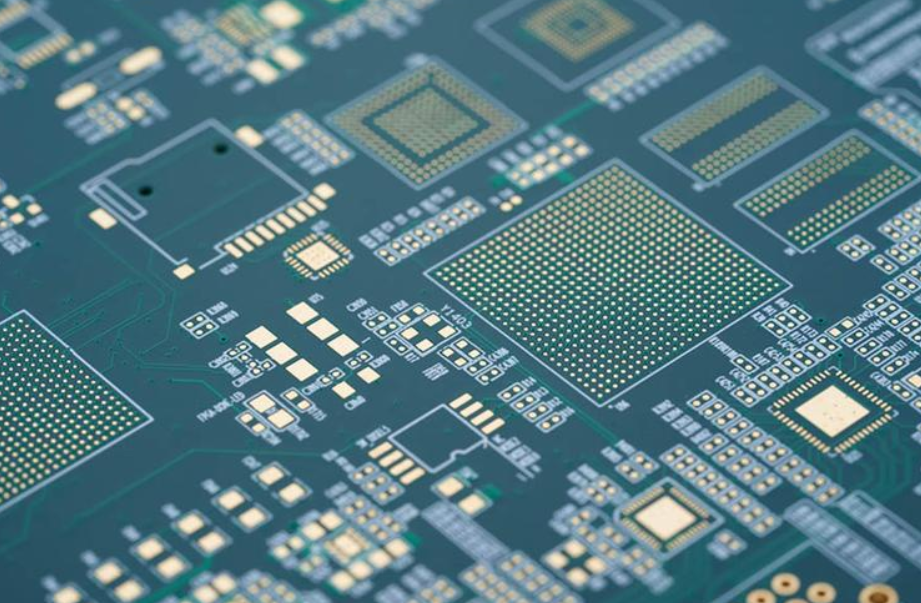

High Density Interconnect PCB: FastTurnPCB’s Value-Added Services for PCB and PCBA Projects

In an increasingly competitive electronics market, manufacturers are no longer looking for just basic PCB fabrication or assembly. They need end-to-end solutions, technical expertise, speed, and reliability—especially when working with complex designs like high density interconnect PCB (HDI PCB). This is where FastTurn PCB stands out. Beyond standard manufacturing, FastTurnPCB offers a wide range of value-added services that help streamline PCB and PCBA projects, reduce risk, improve quality, and accelerate time-to-market.

Why Value-Added Services Matter in PCB & PCBA Projects

Modern electronics demand smaller footprints, higher performance, and greater reliability. HDI PCBs are widely used in applications such as consumer electronics, automotive systems, medical devices, telecommunications, and industrial automation. These advanced boards involve:

- Fine-line traces and tight spacing

- Microvias and multilayer stackups

- High component density

- High-speed and high-frequency signals

Without value-added support—such as design optimization, component sourcing, testing, and logistics—projects can easily face delays, cost overruns, or performance issues. FastTurn PCB’s value-added services address these challenges by providing complete lifecycle support for HDI PCB and PCBA projects.

Engineering Support and Design Optimization

One of the most critical value-added services offered by FastTurn PCB is engineering and design support. Early-stage optimization can significantly reduce production risks and costs.

Design for Manufacturability (DFM)

FastTurnPCB’s engineers review designs to ensure:

- Proper trace widths and spacing for HDI layouts

- Optimized via structures (microvias, blind/buried vias)

- Stackup validation for signal integrity and reliability

- Improved yield and reduced rework

DFM analysis helps identify potential issues before fabrication begins, saving time and money while improving overall quality.

Design for Assembly (DFA)

For PCBA projects, FastTurn PCB evaluates component placement and soldering requirements to ensure smooth assembly, especially for fine-pitch and BGA components common in high density interconnect PCB designs.

Advanced HDI PCB Fabrication Capabilities

FastTurn PCB specializes in high density interconnect pcb, using advanced manufacturing processes and equipment to meet demanding requirements.

Key Fabrication Capabilities Include:

- Laser drilling for microvias

- Multilayer HDI stackups

- Fine-line etching and controlled impedance

- High-performance materials for signal integrity

- Rigid, flexible, and rigid-flex HDI PCBs

These capabilities allow FastTurn PCB to produce reliable HDI boards for high-speed, compact, and mission-critical applications.

Turnkey PCBA Services: From Parts to Final Assembly

FastTurn PCB’s turnkey PCBA services are a major value-added advantage for electronics companies. By managing the entire assembly process, FastTurnPCB simplifies production and reduces supply chain complexity.

Component Sourcing and Procurement

FastTurn PCB handles:

- Global sourcing of certified components

- BOM verification and optimization

- Alternative part recommendations during shortages

- Counterfeit prevention and traceability

This ensures component availability, quality, and cost control—especially important for HDI PCBs with specialized components.

Precision Assembly

FastTurn PCB supports:

- SMT and through-hole assembly

- Fine-pitch, BGA, and micro-BGA components

- Multilayer and HDI PCB assemblies

- Low-volume prototypes to high-volume production

Automated assembly lines ensure accuracy, repeatability, and efficiency.

Comprehensive Testing and Inspection Services

Testing is a critical value-added service, particularly for high density interconnect PCB projects where failures can be costly.

Testing Services Include:

- In-Circuit Testing (ICT)

- Functional Testing

- Burn-In Testing

- Automated Optical Inspection (AOI)

- X-ray inspection for hidden solder joints

These testing processes ensure electrical performance, mechanical reliability, and long-term durability across all PCB and PCBA projects.

Quality Assurance and Certifications

FastTurn PCB integrates quality into every step of its value-added services.

Quality Standards and Controls:

- ISO-certified manufacturing processes

- IPC standards compliance

- RoHS and UL compliance

- Full traceability and documentation

- Continuous process monitoring

This rigorous quality framework ensures that every HDI PCB and assembled board meets international standards and customer expectations.

See also: Top 5 Skills You Gain in an Electrical Technician Program

Rapid Prototyping and Fast Turnaround

Speed is a major advantage when working with FastTurn PCB. Their rapid prototyping services allow customers to validate designs quickly and move to production faster.

Benefits of FastTurn Prototyping:

- Quick turnaround for HDI PCB prototypes

- Early functional validation

- Faster design iterations

- Reduced development cycles

This is especially valuable for startups, R&D teams, and companies launching new products.

Logistics, Packaging, and Supply Chain Support

FastTurn PCB’s value-added services extend beyond manufacturing and assembly.

Logistics Support Includes:

- Custom packaging solutions

- Anti-static and moisture-controlled packaging

- Drop-shipping and global delivery

- Inventory management for repeat orders

These services reduce handling risks and ensure PCBs arrive ready for integration or deployment.

Applications of Value-Added HDI PCB Solutions

FastTurn PCB’s value-added services support HDI PCB and PCBA projects across multiple industries:

- Consumer Electronics: Smartphones, tablets, wearables

- Automotive Electronics: ADAS, infotainment, control units

- Medical Devices: Diagnostic and monitoring equipment

- Telecommunications: Networking, RF, and high-speed data systems

- Industrial Electronics: Automation, robotics, and control systems

In all these sectors, value-added services improve efficiency, reliability, and product success.

Why Electronics Companies Choose FastTurnPCB

Electronics manufacturers choose FastTurn PCB because they offer more than just PCB production.

Key Advantages:

- Complete PCB and PCBA lifecycle support

- Specialized expertise in high density interconnect PCB

- Reduced time-to-market and production risk

- Consistent quality and compliance

- Scalable solutions from prototype to mass production

FastTurn PCB acts as a true manufacturing partner, not just a supplier.

Conclusion

As electronic products become smaller, faster, and more complex, value-added services are essential for successful PCB and PCBA projects. With deep expertise in high density interconnect PCB, FastTurn PCB delivers comprehensive support—from design optimization and fabrication to assembly, testing, and logistics.

By partnering with FastTurn PCB, manufacturers gain access to advanced technology, engineering expertise, and end-to-end services that reduce risk, improve quality, and accelerate product development.

Discover how value-added PCB and PCBA services can elevate your next project by working with FastTurn PCB.